Oil management for passenger cars

Reliable lubrication of moving parts with oil in order to reduce mechanical friction is essential for preventing damage in the engine and transmission. The oil circuit also serves as a means of dissipating heat.

Systems for oil management

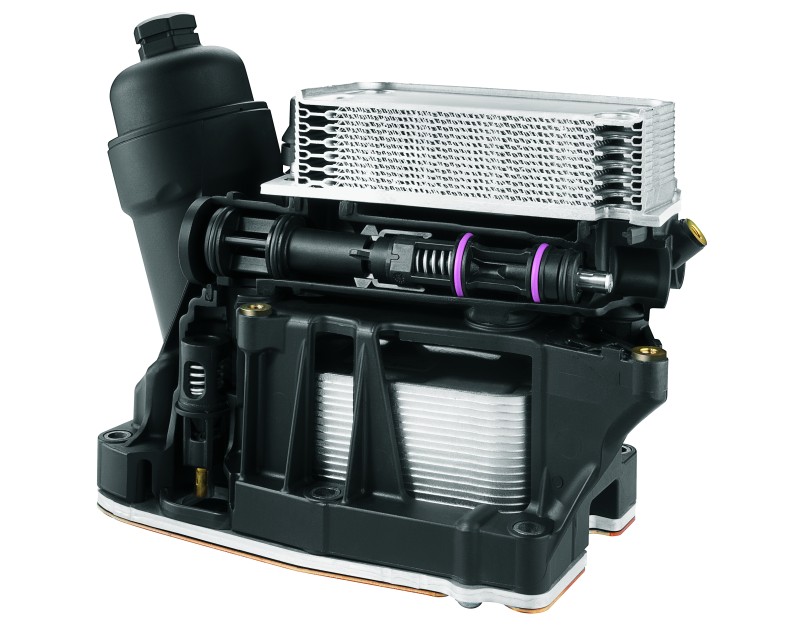

Oil management modules

The development and production of complex oil management modules has long been one of MAHLE’s core competences. When the overall system of “engine lubrication and cooling” is considered, many other functions can be integrated along with the filtration and cooling of the lubricating oil. These include oil mist separation, sensors for pressure and temperature control, oil pressure and crankcase pressure regulation, and the optional incorporation of a fuel cooler. Thanks to the integration and use of state-of-the-art materials—especially of high-performance plastics—, significant cost and weight savings can be achieved. Completely incinerable ecological filter elements that are easy to replace and dispose of are seeing increased use. Long-term filter elements using modern filter media and manufacturing processes provide an essential contribution to the extension of service intervals.

Oil management module for alternative drives

In line with our dual strategy, we are continuing to develop solutions for optimizing the combustion engine, while driving forward e-mobility.

The MAHLE oil management module for alternative drives was designed specifically for the requirements of the electric powertrain, with a focus on weight, packaging, and NVH. It combines an electric oil pump, filter, and thermal management system in one compact unit that cools and lubricates the transmission and electric motor.

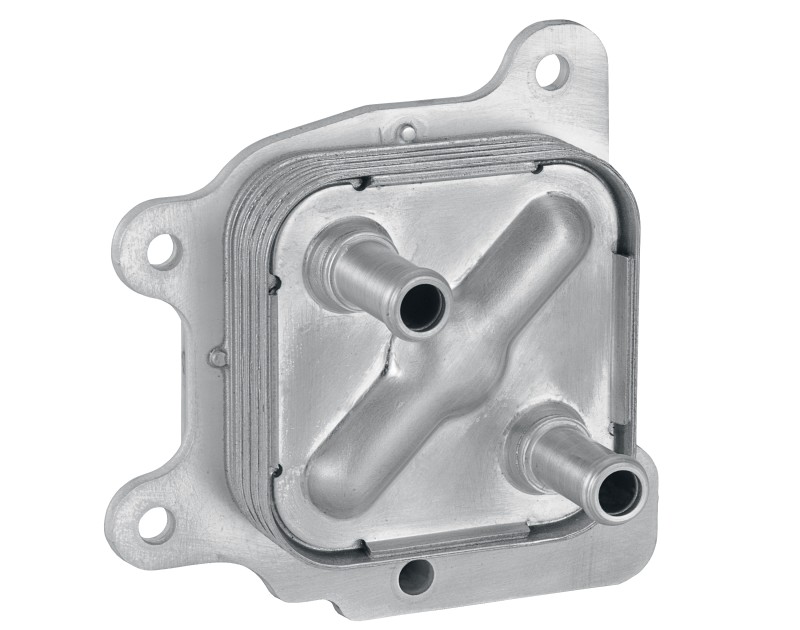

Oil heating and cooling systems

Heat exchangers for heating and cooling modules typically have a lamellar design and ensure an as balanced as possible thermal cycle for lubricating oils in the engine and transmission. This allows the lubricant to heat up quickly, which significantly reduces fuel consumption at cold start. At high oil temperatures, heat exchangers prevent overheating and premature aging of the oil, allowing oil change intervals to be extended.

Current MAHLE heating and cooling modules are also able to handle channel guidance, temperature regulation, and filtering of the coolant flow. An optimized channel guidance and distribution of the coolant flow provides coolant to the heat exchangers of the engine and transmission as well as for fuel as needed.

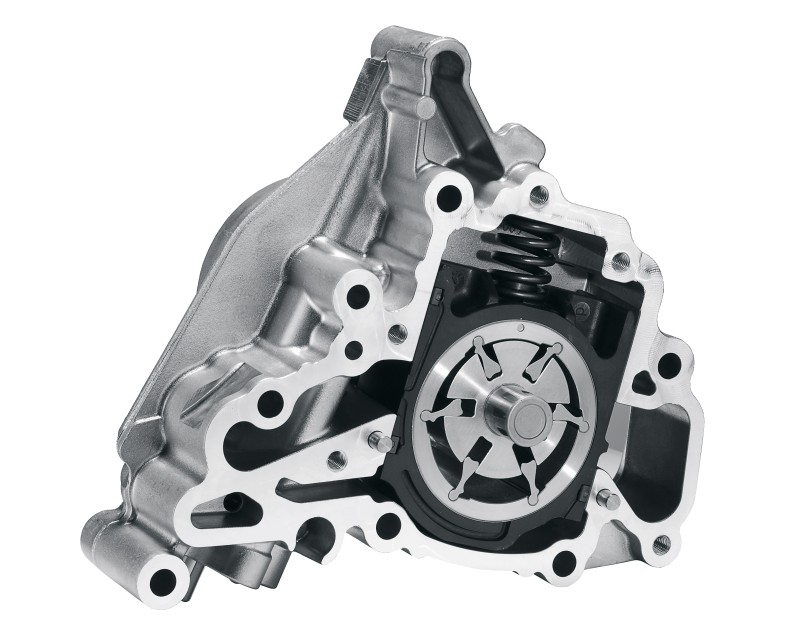

Oil pumps

In order to lower the overall emissions of combustion engines, each and every component must be optimized. One innovation in oil management is the controlled pendulum-slider oil pump from MAHLE. Its high efficiency and smart, demand-based supply of oil pressure and volume offer great potential in terms of reducing CO2 emissions and fuel consumption. This translates to a potential CO2 reduction in the New European Driving Cycle (NEDC) of up to two percent compared with a conventional oil pump.