「開発魂」その100年

マーレは人々の移動を100年に渡って支え続けてきました。

1920年。狂騒の'20年代の始まりです。チャールズ・リンドバーグが大西洋飛行に成功し、アルバート・アインシュタインがノーベル賞を受賞し、マハトマ・ガンジーが非暴力運動を始め、Deutsche Luft Hansa AGが創業、Nuerburgringがオープン。そして、ドイツ・Stuttgart-Bad Cannstatt(シュツットガルト・バートカンシュタット)では、グローバル企業へと育つ種を育て始めようとしていました。ヘルマン・マーレとエルンスト・マーレの兄弟が開発した製品は後に市場を席巻するベストセラーとなり、今日「革新者」として世界に名を馳せる企業の礎となる評価を築いたのです。

現在マーレは従業員約72,000人を擁する世界トップ20の自動車部品サプライヤーとしてその地位を確立し、未来の高効率なモビリティの開拓者としての役割を担っています。マーレは代替駆動の開発及び内燃機関の最適化においても革新的なソリューションを生み出し、世界の新たなスタンダードを創り続けています。

マーレを突き動かすものは何でしょう?それは効率的で、快適な人々の移動を実現したいという思いです。産業界と政治、そして社会との連携を通し、現代の課題に取り組み、その動向に注目していきます。マーレは持続可能なモビリティの創造者です。そして、財団を株主とする企業として、社会的責任を果たしていきます。

今日、そして未来へ。これからの世代、そして次の100年へ。

沿革

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

- •

マーレの沿革について詳しく知ってみませんか?

MAHLE chronicleMAHLE Greatest Hits

MAHLE has been shaping mobility for 100 years. In the MAHLE Greatest Hits series, MAHLE’s most acclaimed innovations of the past and present tell their own tales of how they promoted mobility. Then we will also take a glimpse into the future, how upcoming MAHLE innovations will contribute in our quest to shape the future of mobility.

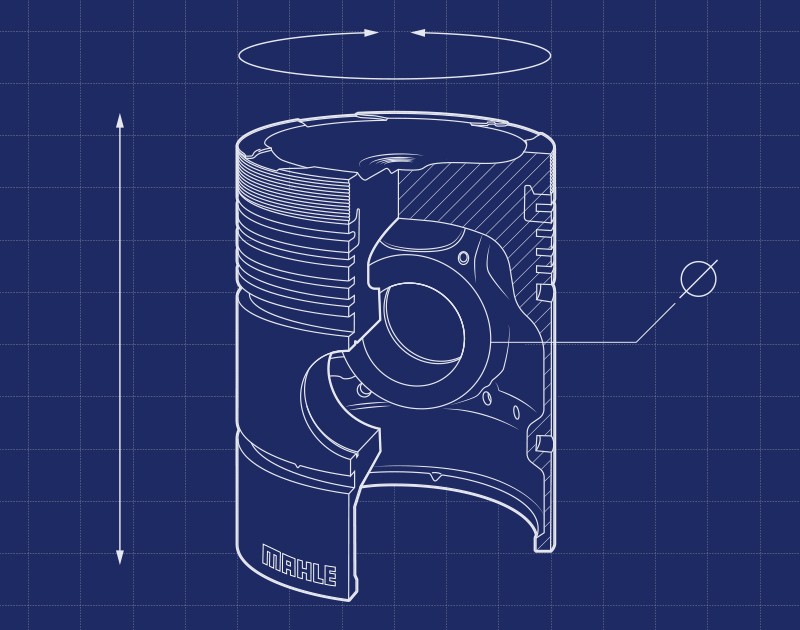

The ring carrier pistion

“I was the key to MAHLE’s success”

“MAHLE’s 100-year success story originates with me! Painstaking research and innovative strength have been permanent fixtures at MAHLE ever since 1920. Pistons were the company’s core business—and I, the patented ring carrier piston, was MAHLE’s first best seller!

My inventor, Ernst Mahle, was a great pioneer. He made sure that I improved the seal in diesel engines and thus reduced the wear and tear they were exposed to. That was the crucial breakthrough that significantly extended the life of an engine. It wasn’t long before I could be found on every road in the world!

Because MAHLE has always driven the mobility of the future, I too have kept on developing. I’ve never been more resilient than I am today. You can find me in vintage cars—and you’ll now also see me coming out of the 3D printers at MAHLE! Its knowledge about me also helps MAHLE to develop new products, such as solutions for alternative drives.”

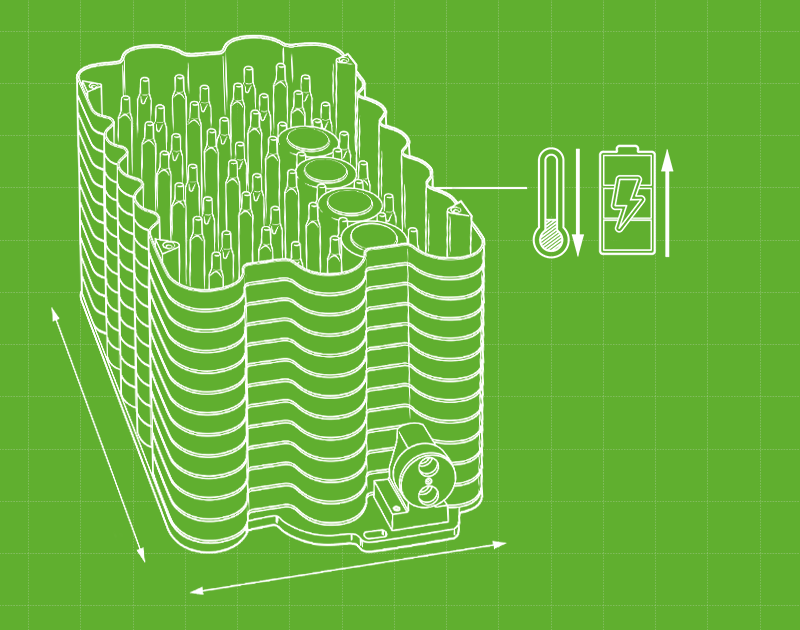

Battery cooling

“I protect batteries for numerous vehicle manufacturers around the globe”

Batteries are one of the keys to the success of e-mobility. But they’re sensitive and need to be kept comfortable at an optimal temperature if they’re to last a long time. That’s why my arrival on the market in 2009 was such great news: I’m the world’s first refrigerant cooling solution for lithium-ion batteries!

My jacket is a cooling plate made of aluminum. There are channels inside me through which the refrigerant evaporates. This keeps the temperature of the cell core within the optimal range. I was installed in a hybrid vehicle first.

Since my world debut, MAHLE has continued to improve my design. These days, I protect batteries for many vehicle manufacturers around the globe. And thanks to immersion cooling, there’s now a new generation of battery systems that allow electric vehicles to be charged much more quickly without causing damage to the cells. With these developments, MAHLE demonstrates its innovative strength in shaping future mobility!

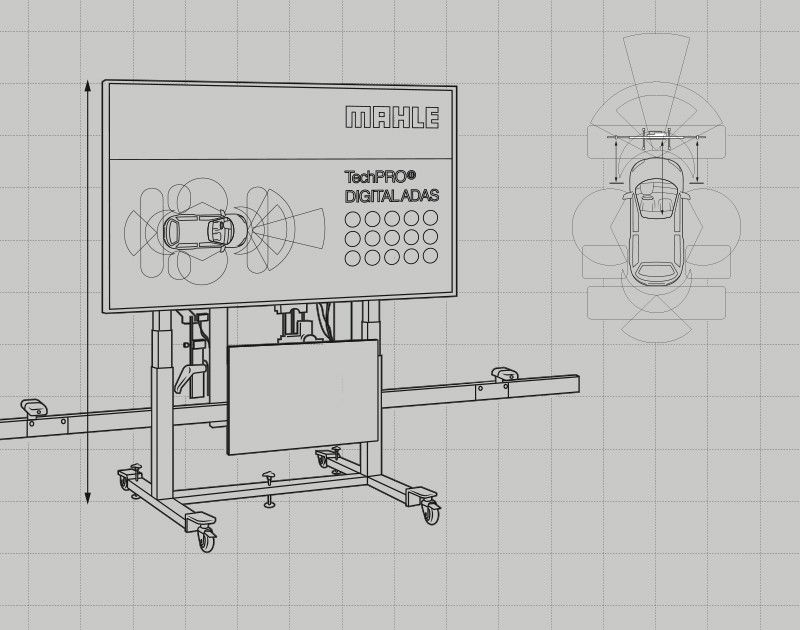

TechPRO® Digital ADAS

“Thanks to me, workshops can breathe a sigh of relief”

“I’m always on hand during the replacement of a windshield or other parts of a car on which important driving aids are mounted. These days, more and more cars are fitted with radar and cameras. This means that workshops are faced with a big challenge when it comes to resetting driver assistance systems after an accident, for example.

Before MAHLE invented me in 2018, technicians had to position a large, cumbersome panel in front of each car—and there was a different one for every vehicle model. These panels act like opticians, helping to orientate assistance systems so that they can tell up from down and back from front. As a result, calibration used to be a complex process.

When I, TechPRO® Digital ADAS, came on the scene, workshops around the world could finally breathe a sigh of relief! I combined the panels in one digital flat-screen display, which works for almost all manufacturers and models. Thanks to me, workshop technicians can calibrate driver assistance systems in just ten minutes. The number of cars with driver assistance systems will keep on increasing. This means that I’m in high demand—with customers asking for me every day.”

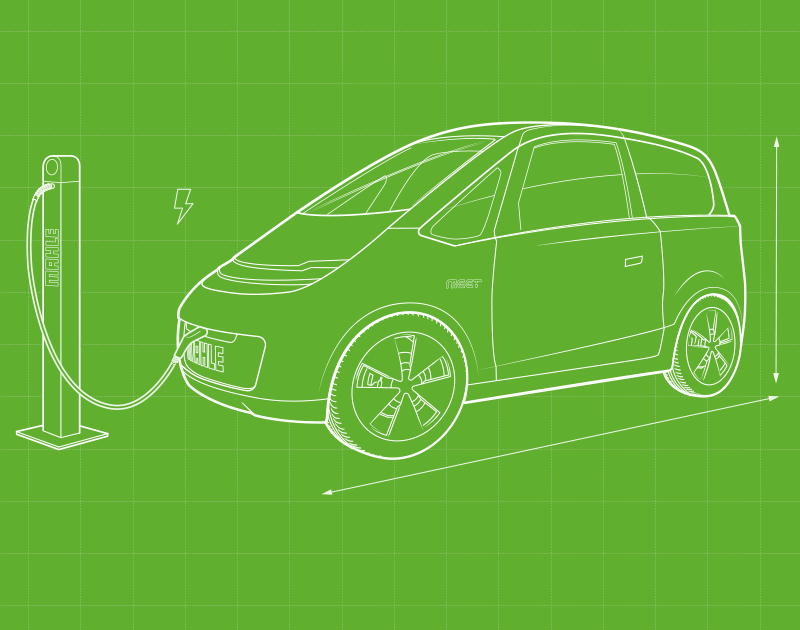

MAHLE MEET

“I showcase MAHLE’s innovative strength”

“In the future, a large proportion of the world’s population will live in cities. That means that city cars will be an important element of future mobility. MAHLE has seized this opportunity to develop a mobility concept that is both urban and climate-friendly—me!

My name is MAHLE Efficient Electric Transport, my friends call me MEET. I’m a light, agile vehicle concept with space for two people, and my design integrates MAHLE powertrain and thermal management technologies for e mobility!

From my 48-volt drive unit to my power electronics, efficient heat pump, and surface heaters through to my user interface, I showcase MAHLE’s comprehensive portfolio and innovative strength. I embody MAHLE’s commitment to play an active role in shaping future mobility.”

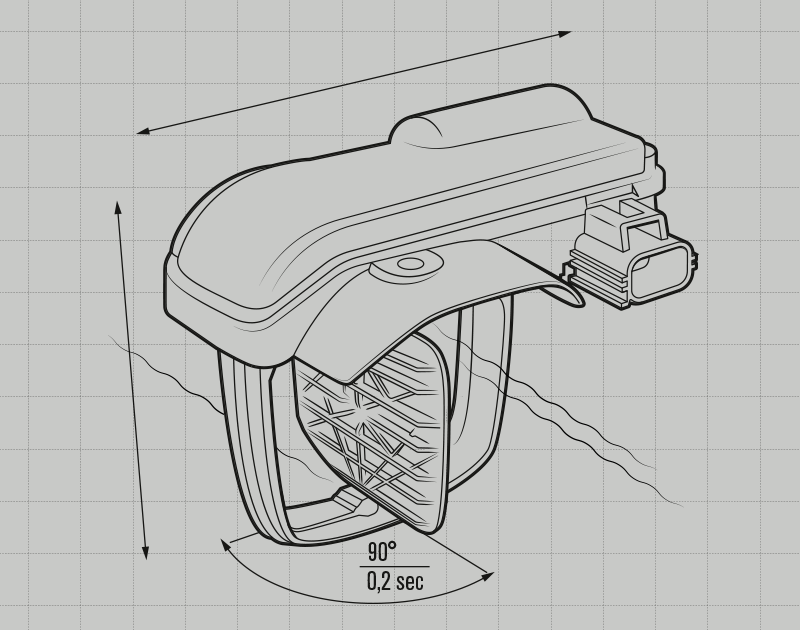

Intake pipe actuator

“All of MAHLE’s mechatronics activities started with me”

In truth, I am rather plain—nevertheless, I ushered in a new era at MAHLE. MAHLE’s activities in the field of mechatronics started with me, the intake pipe actuator. I’m the first product in this area that MAHLE developed and produced itself.

I make sure that the air column in an engine’s intake section resonates at the right frequency and enters the cylinder smoothly. My housing is lightweight and sturdy, and I work very precisely and quickly: I can open 90 degrees in 200 milliseconds.

Since I went into production in 2005, MAHLE has been steadily advancing in the field of mechatronics. The new Electronics and Mechatronics business unit was created at the start of 2020. This is where MAHLE has pooled all its activities in the segment and is developing the technologies of the future.

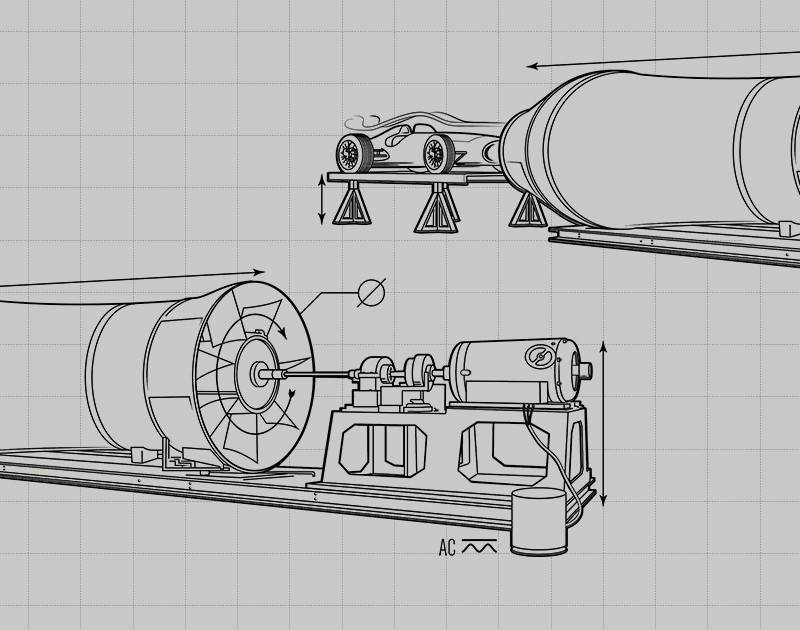

Wind tunnel

“I was a world first”

“When my creator, Manfred Behr, invented me in 1937, people probably didn’t find me outwardly attractive—but when they looked inside, I took their breath away! On the outside, I had the appearance of a modest corrugated iron shed, but inside something completely new was happening: I was a world first—the first wind tunnel anywhere in the automotive industry.

A huge fan with a 2-meter diameter simulated speeds of up to 100 km/h. My success was so groundbreaking that I even optimized the most famous race car of my time.

I’m still around today—and I’ve learned so much since I started out. As MAHLE’s climatic wind tunnel, I’ve been creating temperatures ranging from –30°C to +50°C since the majority acquisition of BEHR (in 2013). I can also simulate the position of the sun at all times of the day and generate speeds of up to 130 km/h, all of which helps MAHLE to develop the mobility of the future.”

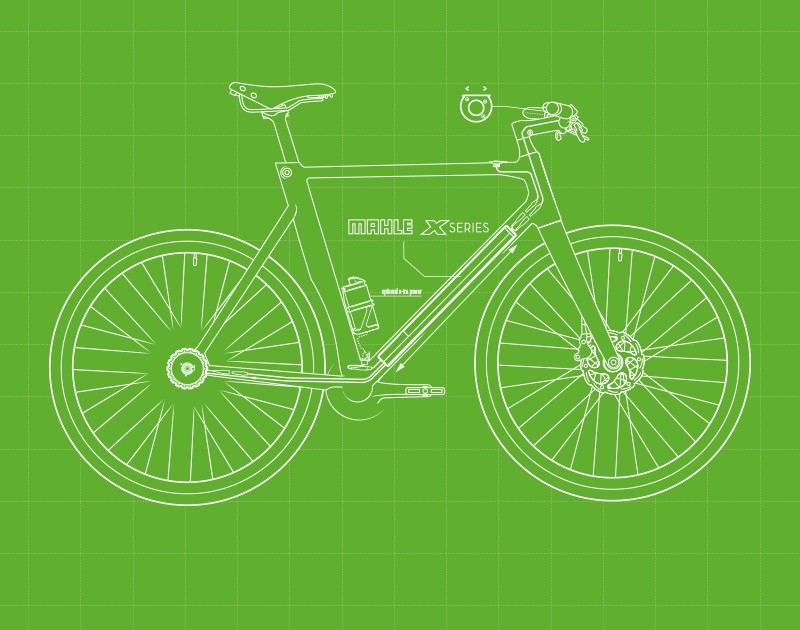

MAHLE X35

„I gave the bicycle back its identity“

“E-bikes are one of the biggest trends in today’s mobility—there are more and more of them out on the world’s cycle paths and mountain bike trails. But thanks to the way they look, they can almost rob the bicycle of its identity. That’s because large batteries don’t just make e-bikes bulky and heavy, they also change their outward appearance. Then I came along—the MAHLE X35—and gave the bicycle back its identity!

It’s thanks to me that the e-bike is so slim, elegant, and sporty—you would hardly know that I’m a drive system. I offer users an optimum level of support. After all, as I always say, it’s not the maximum but rather the ideal performance that counts!

With my updated MAHLE X35+ compact system, I now weigh just 3.5 kilograms and provide a power output of 250 watts. What’s more, I’m digitally connected too. My app displays the rider’s pulse or how much of my electric power is being used. You’ll find me in models sold by a whole range of well-known international e-bike brands. I’m helping MAHLE play an active role in shaping sustainable mobility!”

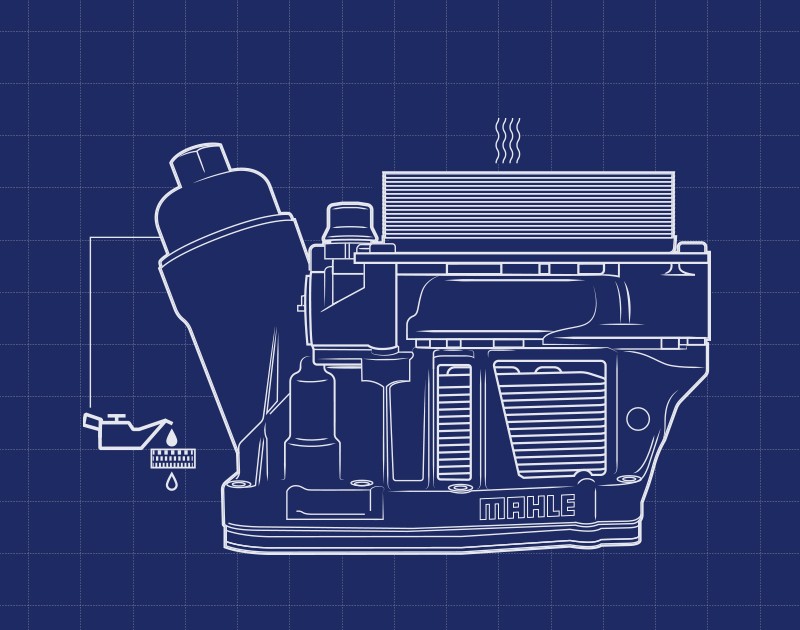

Oil filter module

“I’m a revolution in oil management”

MAHLE’s success story has its origins in pistons and filters. But, in contrast to its pistons business, the company stopped its filter activities in 1941 due to the war. Then, in 1971, MAHLE made its comeback in this product area by taking a significant holding in Knecht Filterwerke.

I am the oil filter module—a shining example of the continued ongoing development work and impressive know-how of MAHLE’s filters business segment! I say that because I’m a revolution in oil management. I have many talents, keeping the engine and the transmission oil in the right temperature range as well as filtering the engine oil, of course. But I’m still lightweight and compact.

I made my debut on the market in 2010 and can be installed in almost any car—even in hybrid vehicles. I demonstrate MAHLE’s innovative strength in the filters business segment!

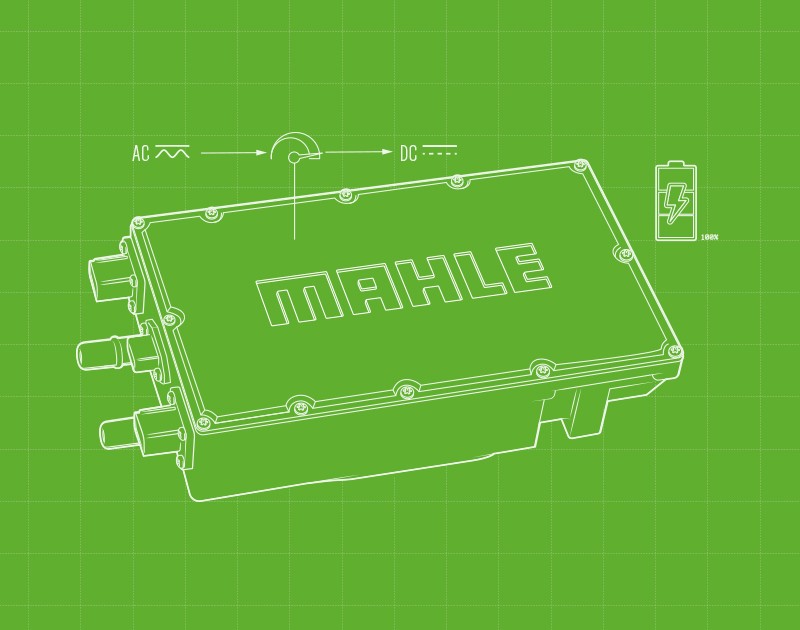

Onboard charger

“I charge electric vehicles quickly anywhere”

For e-mobility to become established on our roads in the long term, it must be possible to charge electric vehicles quickly and in any location. So that this can happen anywhere, MAHLE developed me: the onboard charger.

Thanks to me, electric vehicles can be charged at any power outlet. That’s because I turn alternating current into direct current and manage the charging process. By doing this, I help to significantly prolong the life of the battery. Because I’m robust and have a clever cooling system, I also facilitate short charging times at higher capacities.

I still have a lot more to offer—and MAHLE, an active driving force behind future mobility, is set to unlock this potential. For example, I will be able to help electric cars not only consume energy but also become electricity suppliers using a smart battery.

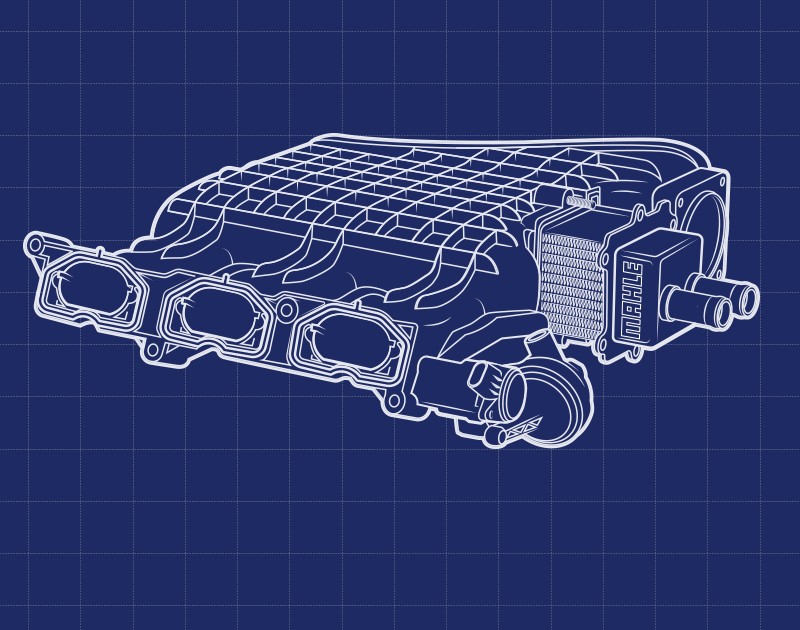

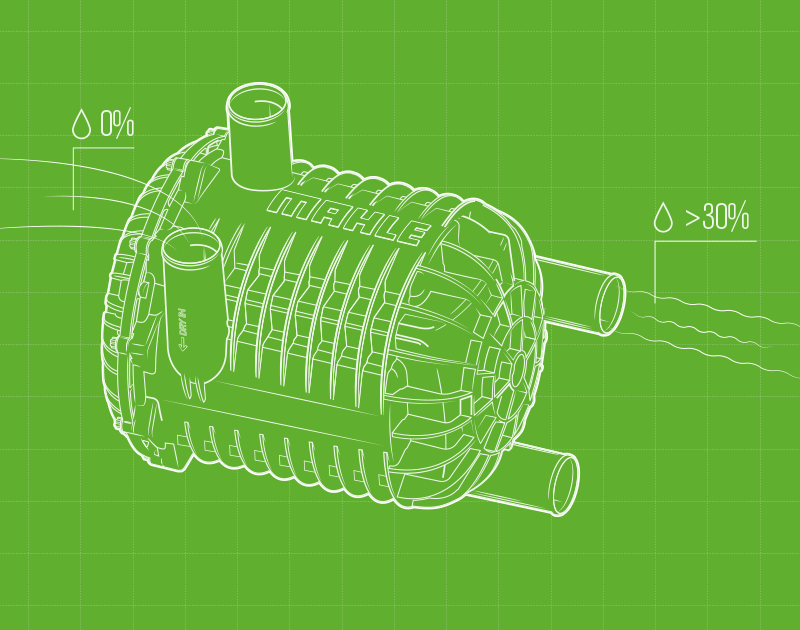

Air intake module with integrated charge air cooling

“I’m the innovative result of outstanding teamwork!”

Together, MAHLE and BEHR are greater than the sum of their parts! I was the first to prove the truth of this maxim. In 2011, I was the first project that MAHLE and BEHR worked on together: the air intake module with integrated indirect charge air cooling.

What’s special about me is that my charge air cooler—produced by BEHR—is integrated directly in the intake pipe—produced by MAHLE. This means that not only do I reduce pressure loss, and therefore boost efficiency, but I also create more installation space and increase cooling capacity.

I’m a major success story! Because I represent an important step forward in the development of modern combustion engines, I’m now the market leader and installed in vehicles around the world. And, thanks to the combined expertise of MAHLE and BEHR, I’m the innovative result of outstanding teamwork!

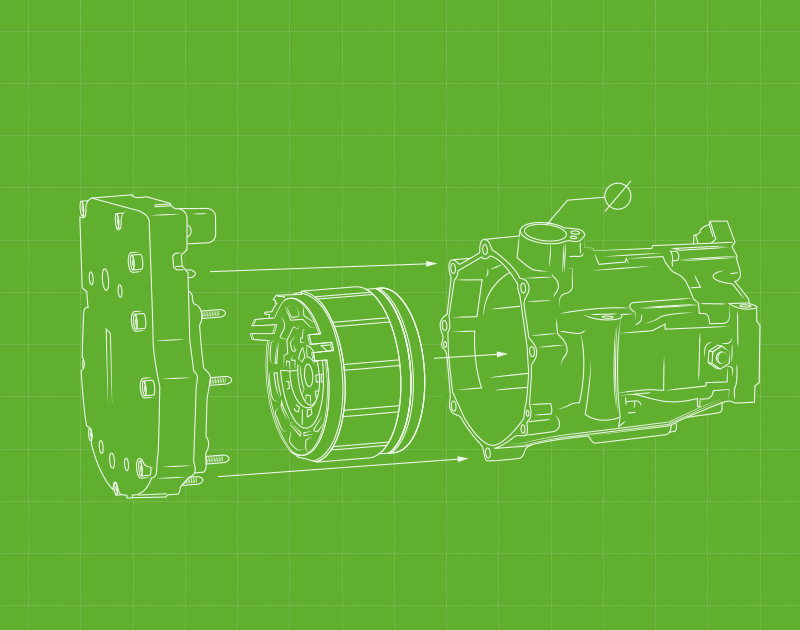

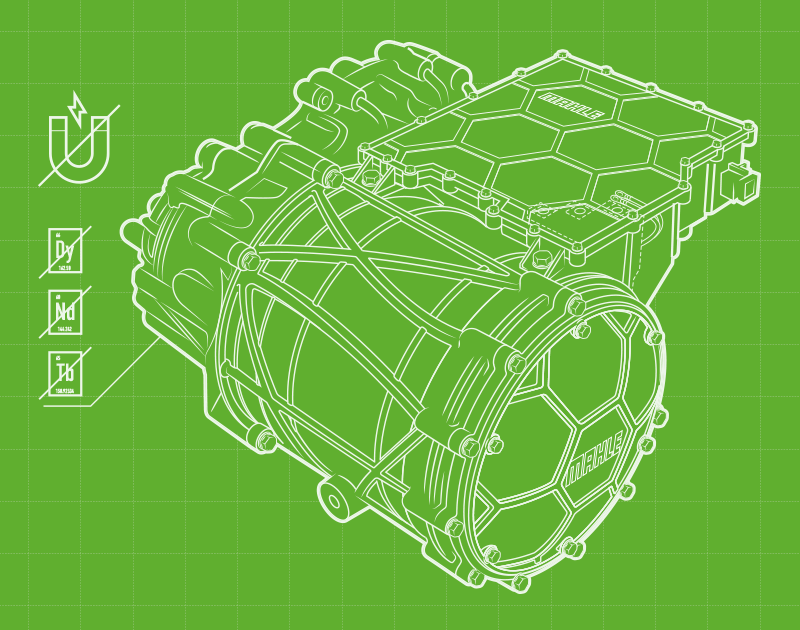

The magnet-free high-voltage motor

“I don’t need any rare earth elements, so I’m very sustainable”

Electric vehicles will be an important part of future mobility. Because they need to be sustainable, suitable for everyday use, and cost-effective, MAHLE developed a drive concept that’s ideal for a wide range of electric vehicle types—me!

I’m the magnet-free high-voltage motor, and I can be used in anything from subcompacts through commercial vehicles. I’m particularly noted for the fact that I get along fine without magnets. That makes me more sustainable, because I don’t need any rare earth elements. What’s more, the way I operate means that electrical current is transmitted with no wear, and I’m also efficient in the partial-load range.

I plan to go into series production very soon, and I’ll be produced by our newly established Electronics and Mechatronics business unit. I’m helping MAHLE play an active role in shaping sustainable e-mobility!

Flat membrane humidifier for fuel cell vehicles

“I’m an example of MAHLE’s great innovative strength”

Supplying air to a fuel cell is extremely challenging. That’s because, unlike in a combustion engine, the air also needs to be humid so that the system works smoothly and efficiently. My role as the flat membrane humidifier is to ensure that the moisture content in the air is just right—protecting the fuel cell against damage!

I’m an example of MAHLE’s great innovative strength. I’m compact and robustly built, and I always keep the supply air at the optimum humidity level. I’m so innovative that I even receive funding from the German Federal Ministry for Economic Affairs and Energy (BMWi)!

MAHLE has been working on my development since 2017, with everything coming together in the fuel cell project house, and I’m set to go into series production in 2023. I’m helping MAHLE play an active role in shaping a key powertrain of the future!

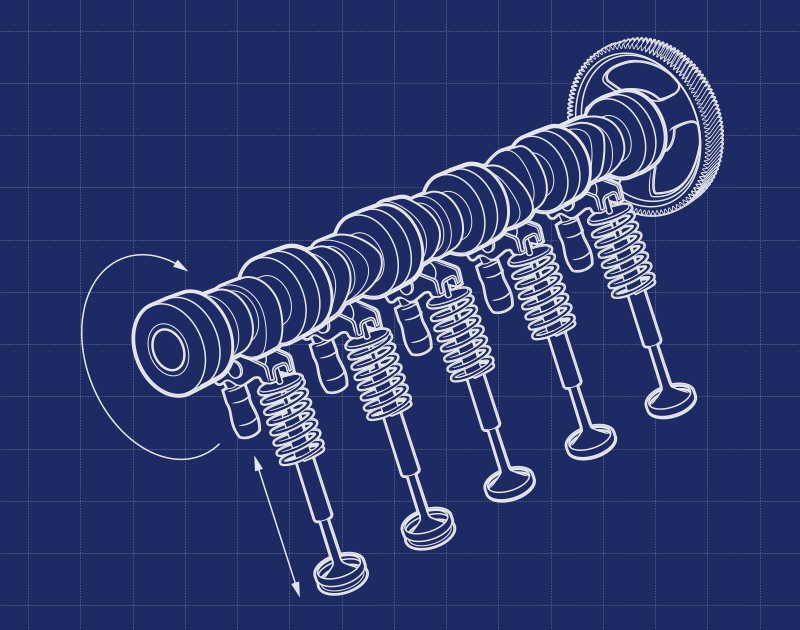

Valve train system

“I am the lungs of the engine”

“If you were to think about the components in an engine as organs, then I’d be its lungs. That’s because I make sure that the engine breathes in the right amount of fresh air for the combustion process at the right time and breathes the burned air back out again.

I’m the valve train, and I’ve been a key part of the MAHLE portfolio since the acquisition of Wizemann (in 1991) and Pleuco (in 1994). When I joined the company, MAHLE greatly expanded its wide-ranging knowledge base covering all aspects of the engine—and the team has kept on developing me.

I’m very flexible nowadays, and my perfect timing allows me to help engines reduce their pollutant emissions, consume less fuel, and yet still deliver a higher performance.”